when the diamond mesh is leveled

What should be paid attention to when the diamond mesh is leveled?

1. The diamond-shaped mesh coating and the galvanized steel strip have a flatness of 0.5% when the thickness is not more than 0.70 mm.

2. The diamond mesh usually requires strict control of the flattening rate of the cold-rolled strip for deep drawing.

3. When there is a platform strip, there will be a slip line during the stamping process. When bending into a circle, there will be a tendency of lateral folding, which will result in poor surface quality of the workpiece. Therefore, the flattening process should adopt the corresponding flat elongation to achieve the adjustment. Performance purpose

4. In the process, the diamond mesh has control requirements for the flatness of each steel coil, and the whole material steel coil must have a stable rate.

5, using tin plate, requires a certain strengthening deformation to adjust the strength and hardness, the flat elongation is 1% -3%

6, diamond-shaped net for deep-drawing automotive sheet, because the requirements for restrictions are very low and eliminate the platform, it is generally considered that the best flat elongation range is 0.8% - 1.4%

-

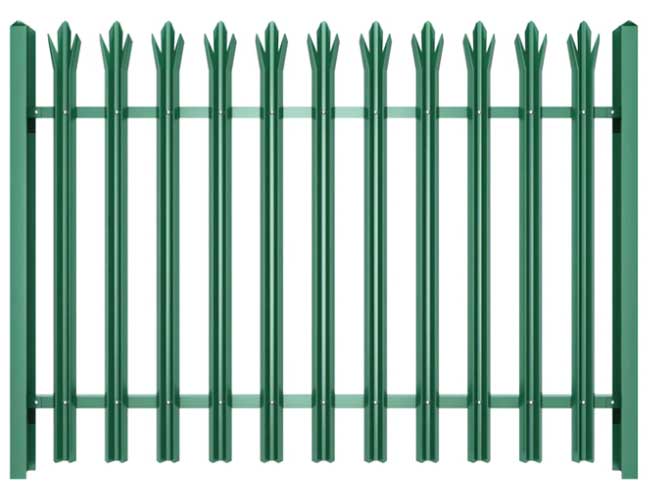

What Kind Of Fence Is Best For Your Yard 06. 04, 2021

What Kind Of Fence Is Best For Your Yard 06. 04, 2021 choose PVC fences during the purchase process 04. 22, 2020

choose PVC fences during the purchase process 04. 22, 2020 PVC fences are mostly used for municipal PVC fences 04. 22, 2020

PVC fences are mostly used for municipal PVC fences 04. 22, 2020 Detailed use of wire mesh fence 04. 22, 2020

Detailed use of wire mesh fence 04. 22, 2020 Advantages of Airport Fence 04. 22, 2020

Advantages of Airport Fence 04. 22, 2020 -

The role and advantages of airport fence nets 04. 22, 2020

The role and advantages of airport fence nets 04. 22, 2020 Features of Gabion Basket 04. 22, 2020

Features of Gabion Basket 04. 22, 2020 The steel wire mesh cage 04. 22, 2020

The steel wire mesh cage 04. 22, 2020

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: +86 180 3241 2189

- Ajouter.:No.69-70 La partie industrielle du filtre d'Anping, Hebei, Chine