Présentation:

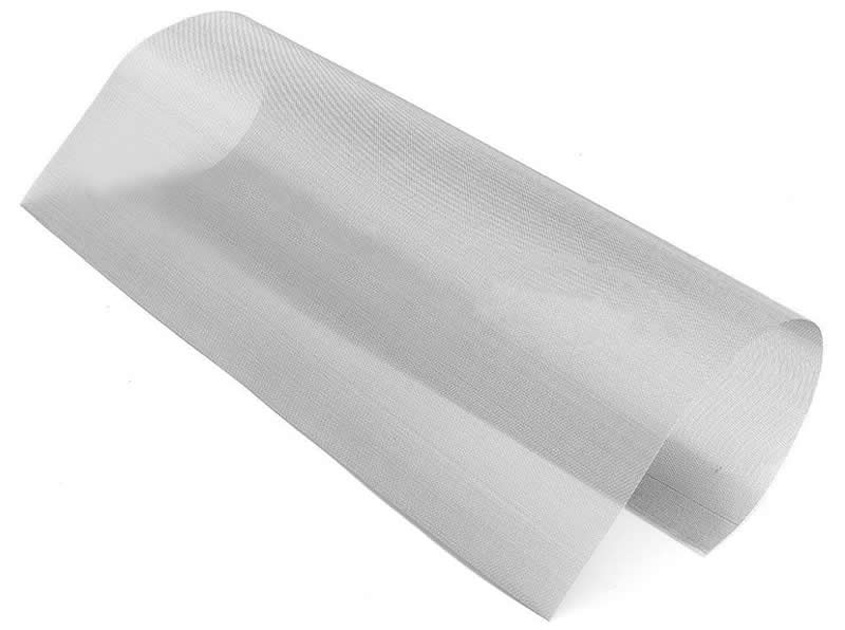

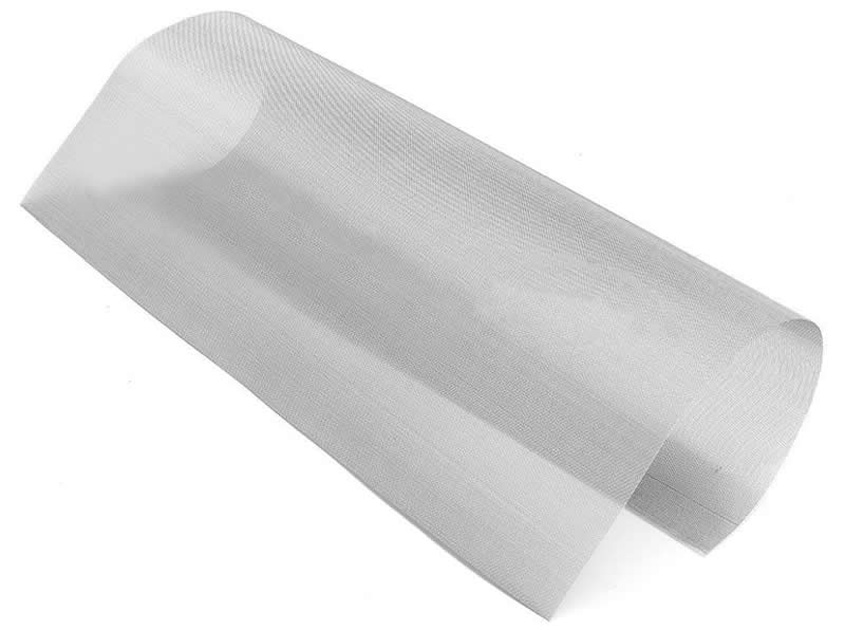

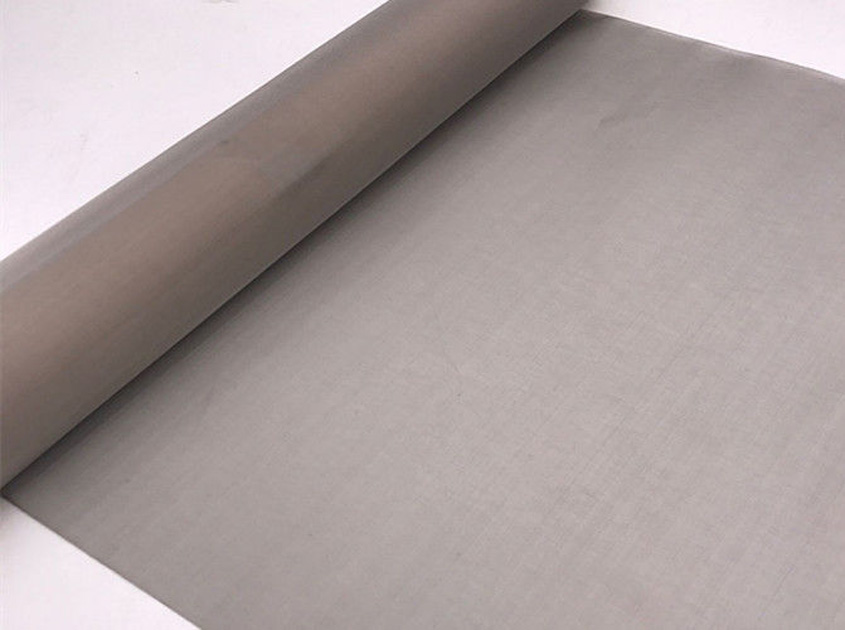

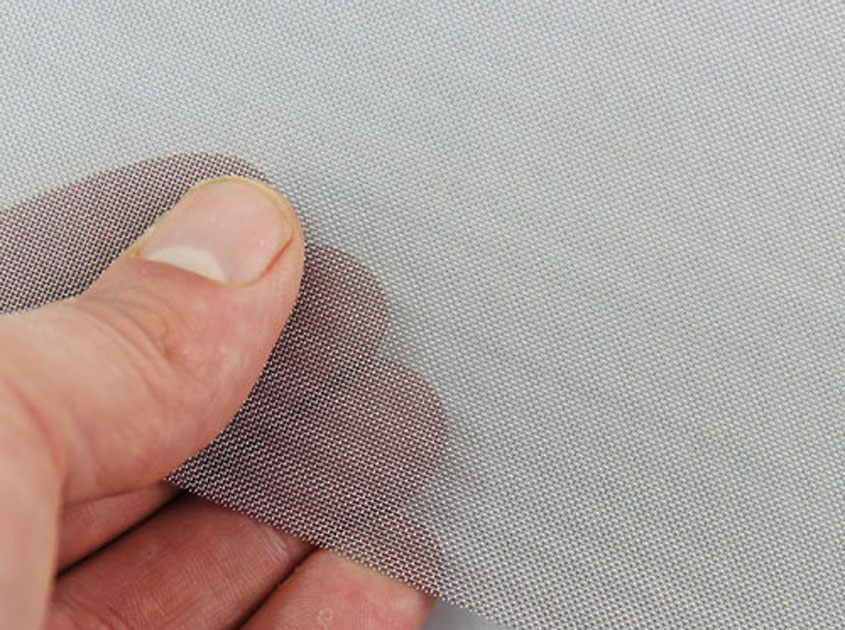

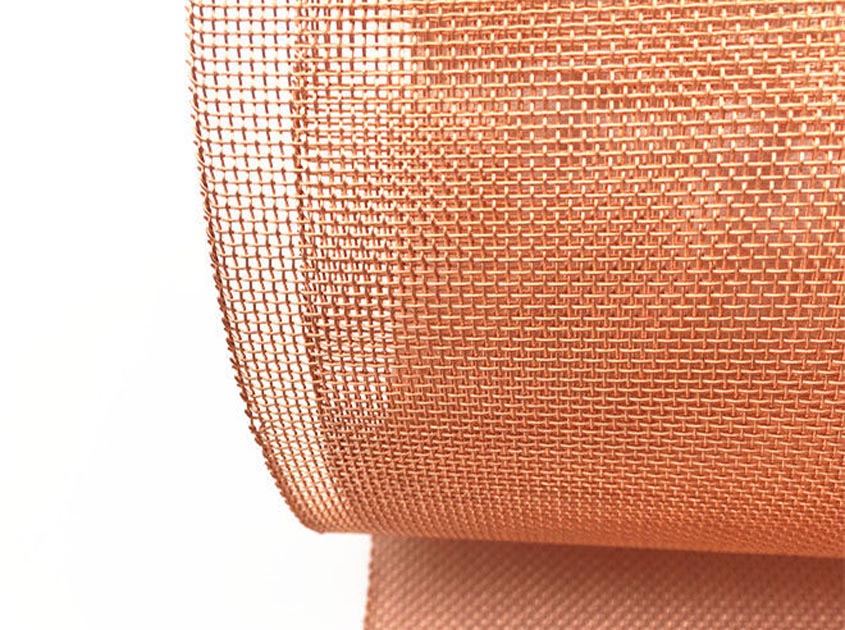

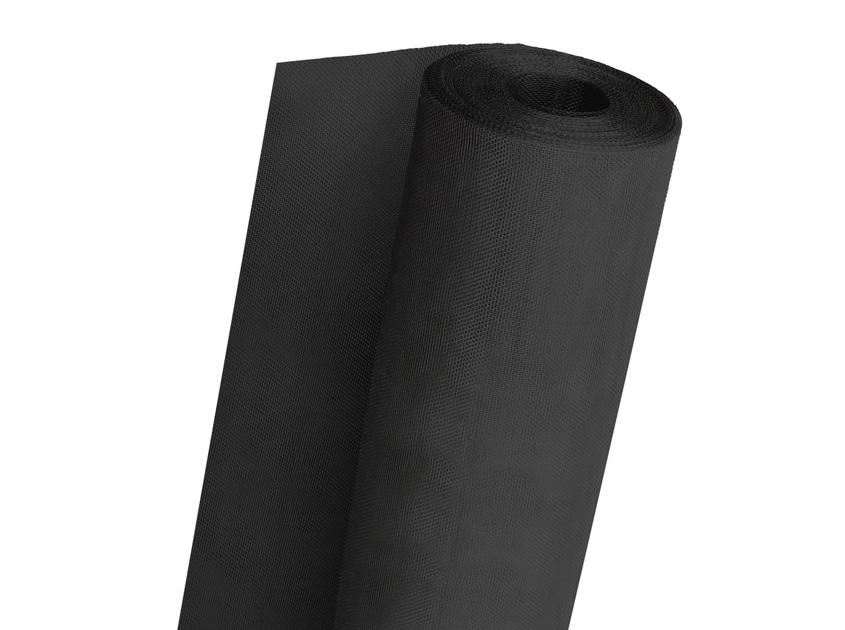

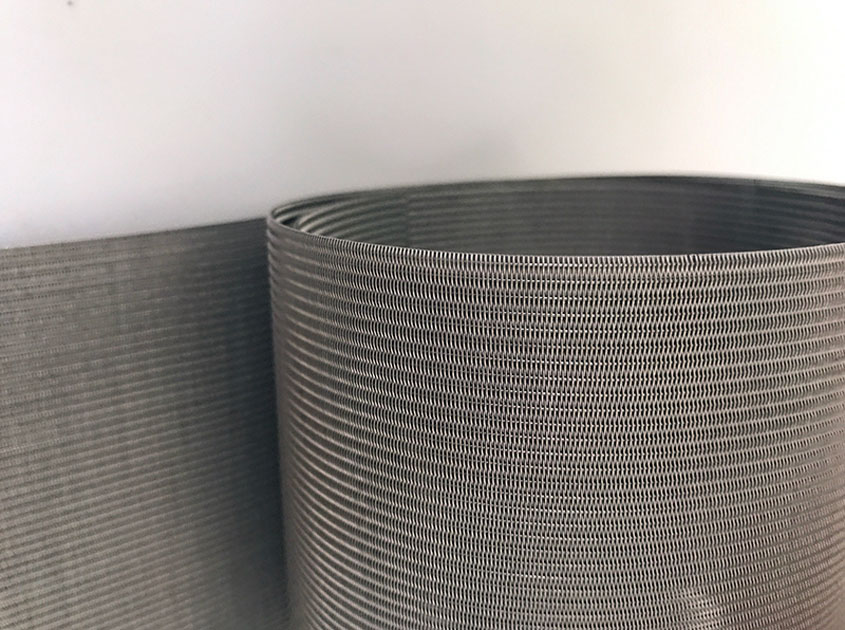

The Monel wire mesh, similar to the inconel wire mesh, it is also a type of woven mesh, which is weaved from nickel-based alloy wire. Monel is the alloy of nickel, copper and other chemical elements. According to different chemical elements, the monel wire mesh has Monel alloy 400 and monel alloy K500 materials.

Alloy 400 has outstanding corrosion resistance property in the flowing sea water. It can also resist to stress corrosion cracking. Alloy 400 is the most widely used monel material.

Alloy K500 also has outstanding corrosion resistance property like the Monel alloy 400, but the Monel alloy K500 has been added aluminum, which can let the monel K500 offer greater tensile strength and hardness than the Monel alloy 400.

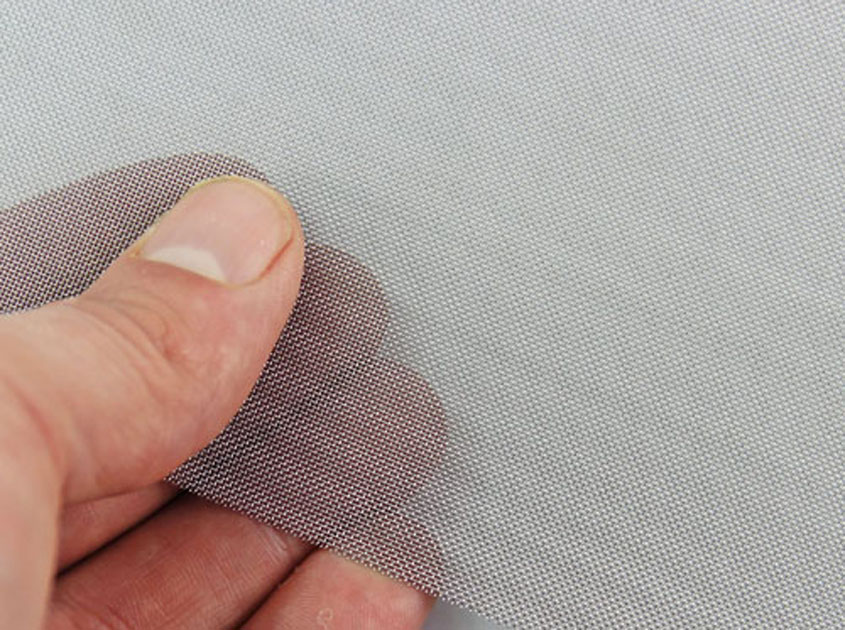

The monel wire mesh includes fine woven wire mesh, which has the mesh size larger than 80 meshes, and coarse woven wire mesh with the meshes no larger than 80 meshes.

Features of Monel Wire Mesh:

Monel wire mesh has the features such as: Superior corrosion resistance and acid-alkali resistance; High temperature resistance; Resistance to stress corrosion; High tensile strength; Excellent hardness.

Chemical Composition:

| Material | C | Mn | Si | S | Ni | Cu | Fe |

| Monel 400 | ≤0.30 | ≤2.00 | ≤0.50 | ≤0.024 | ≥63 | 28.0~34.0 | ≤2.5 |

| Material | C | Mn | Si | S | Ni | Cu | Ti | Al | Fe |

| Monel K500 | ≤0.25 | ≤1.50 | ≤0.50 | ≤0.010 | ≥63 | 27.0 ~33.0 | 0.35 ~0.85 | 2.30 ~3.15 | ≤2.0 |

Applications of Monel Wire Mesh:

Monel wire mesh can be widely used in chemical and petrochemical industry and marine development etc. Monel wire mesh also can be used to manufacture all kinds of heat exchange equipment, pressure vessel, boiler feed water heater equipment, oil and chemical pipelines, containers, towers, tank, valves etc.

Caractéristiques:

1. Corrosion resistance in the sea water.

2. Corrosion resistance in the chemical solvent.

3. Corrosion resistance in the acidoid, such as hydrofluoric acid, phosphoric acid.

4. Corrosion resistance in the alkaline matter.

5. Resist to stress corrosion cracking.

6. High tensile strength.

7. Excellent hardness.

8. Long lasting and durable.

Spécifications:

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 8 × 8 | 0.0280 | 0.0970 | 60.20 |

| 10 × 10 | 0.0250 | 0.0750 | 56.30 |

| 12 × 12 | 0.0230 | 0.0600 | 51.80 |

| 20 × 20 | 0.0160 | 0.0340 | 46.20 |

| 30 × 30 | 0.0130 | 0.0203 | 37.20 |

| 40 × 40 | 0.0100 | 0.0150 | 36.00 |

| 60 × 60 | 0.0072 | 0.0090 | 30.50 |

| 80 × 80 | 0.0055 | 0.0070 | 31.40 |

| 100 × 100 | 0.0045 | 0.0060 | 30.30 |

| 120 × 120 | 0.0036 | 0.0047 | 32.26 |

| 150 × 150 | 0.0026 | 0.0041 | 37.20 |

| 200 × 200 | 0.0021 | 0.0533 | 33.60 |

Note: Special size and specifications can be made according to customers requires.

Technologie:

Material: Monel 400, Monel 401, Monel 404, Monel R405, Monel K-500

Weaving: Plain weave, Twill weave

Melting point: 1300 degree-1350 degree

Features of Monel Wire Mesh:

Monel wire mesh has the features such as: Superior corrosion resistance and acid-alkali resistance; High temperature resistance; Resistance to stress corrosion; High tensile strength; Excellent hardness.

Chemical Composition:

| Material | C | Mn | Si | S | Ni | Cu | Fe |

| Monel 400 | ≤0.30 | ≤2.00 | ≤0.50 | ≤0.024 | ≥63 | 28.0~34.0 | ≤2.5 |

| Material | C | Mn | Si | S | Ni | Cu | Ti | Al | Fe |

| Monel K500 | ≤0.25 | ≤1.50 | ≤0.50 | ≤0.010 | ≥63 | 27.0 ~33.0 | 0.35 ~0.85 | 2.30 ~3.15 | ≤2.0 |

Applications of Monel Wire Mesh:

Monel wire mesh can be widely used in chemical and petrochemical industry and marine development etc. Monel wire mesh also can be used to manufacture all kinds of heat exchange equipment, pressure vessel, boiler feed water heater equipment, oil and chemical pipelines, containers, towers, tank, valves etc.

Désignation de Produit: Monel Wire Mesh