THE PRESENTATION AND DIFFERENCE OF TWO GALVANIZATION TECHNOLOGIES

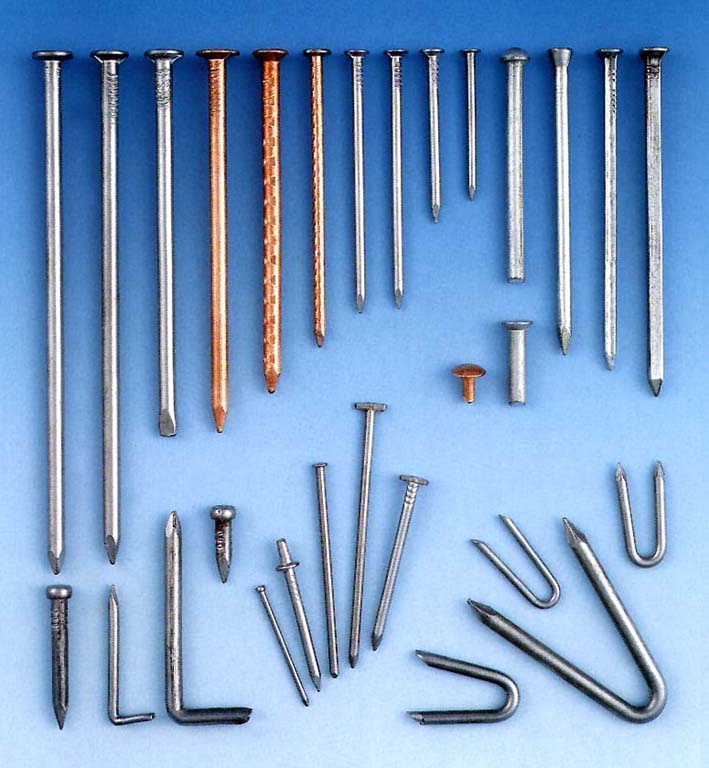

Now in order to improve the service life and corrosion resistance of nails,nail wholesalers will choose the appropriate method of galvanization of in the production and processing of nails, electro galvanized and hot dipped galvanized,usually the both used for Common Nails,let's compare the two galvanization processes with Common Nails example.

1.When electro galvanized plating, the zinc on the Common Nail can be covered well, the surface is smooth,bright and the zinc on the head and shank of nails is totally covered. Moreover, galvanizing is relatively pure, which can guarantee its good anti-corrosive performance. The effect is good,this also the most galvanized type of nails.

2.The hot-dip galvanization method is used to fuse iron ions and zinc ions so that they are tightly combined. The surface of the common nail is not only zinc, but also a mixture of steel and zinc.The surface is silvery white, not very bright as electro galvanized plating,the zinc on the Common Nail also can be covered well.

The usage of common nails has become increasingly demanding in many fields. We need to constantly develop excellent products to win the trust of our customers. Galvanizing can increase its overall use effect, and in use, it can ensure its corrosion resistance and hardness.

The above is all the content brought by the nail manufacturer QUNKUN METAL COMPANY. If you want to know more info, please just continue to pay attention to us.

-

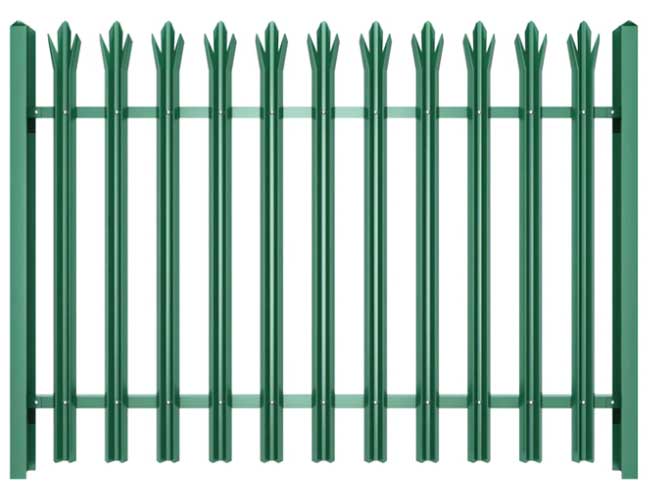

What Kind Of Fence Is Best For Your Yard 06. 04, 2021

What Kind Of Fence Is Best For Your Yard 06. 04, 2021 choose PVC fences during the purchase process 04. 22, 2020

choose PVC fences during the purchase process 04. 22, 2020 PVC fences are mostly used for municipal PVC fences 04. 22, 2020

PVC fences are mostly used for municipal PVC fences 04. 22, 2020 Detailed use of wire mesh fence 04. 22, 2020

Detailed use of wire mesh fence 04. 22, 2020 Advantages of Airport Fence 04. 22, 2020

Advantages of Airport Fence 04. 22, 2020 -

The role and advantages of airport fence nets 04. 22, 2020

The role and advantages of airport fence nets 04. 22, 2020 Features of Gabion Basket 04. 22, 2020

Features of Gabion Basket 04. 22, 2020 The steel wire mesh cage 04. 22, 2020

The steel wire mesh cage 04. 22, 2020

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: +86 180 3241 2189

- Ajouter.:No.69-70 La partie industrielle du filtre d'Anping, Hebei, Chine