Introduction of metal mesh types

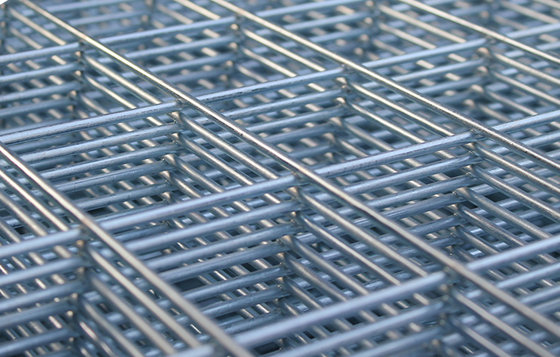

The metal mesh is divided into stainless steel mesh and carbon steel mesh according to the mesh material. Carbon steel mesh: According to the production requirements, it is divided into soft-edge mesh and hard-edged mesh. The metal mesh is made of high-quality Q195 carbon steel. The cold-drawn unit is used to cold-pull the blank wire into the customer's required wire diameter (wire diameter up to 3.0). Mm), the cold drawn steel wire is cut into the length standard required by the customer through the leveling machine and the active cutting machine. The wire with the cut length standard is placed in a special mold (to make the mold according to the customer's mesh standard), welded through a semi-active welding machine, and then trimmed by a trimming machine, the soft edge mesh It can be made. If you want to process the hard-edged mesh, you can weld the soft-edged mesh to the outer frame (the outer frame is usually made of square tube or round tube, and the square tube or round tube is welded according to the customer's requirements). Hard edge mesh.

Since the mesh is the opening between the wires on the mesh surface, the number of holes per inch and the number of wires should be the same, so it can be explained that there are 100 warp (or weft) in the length of 1 inch (25.41 mm). Silk, a 1 square inch net composed of 100 filaments in the longitude and latitude directions, has 10,000 meshes, and its mesh number is 100 mesh.

With the rapid development of science and technology, the current use of wire mesh and petroleum, chemical, automotive, paper, food, construction, aviation, aerospace and other industries and high-tech areas.

-

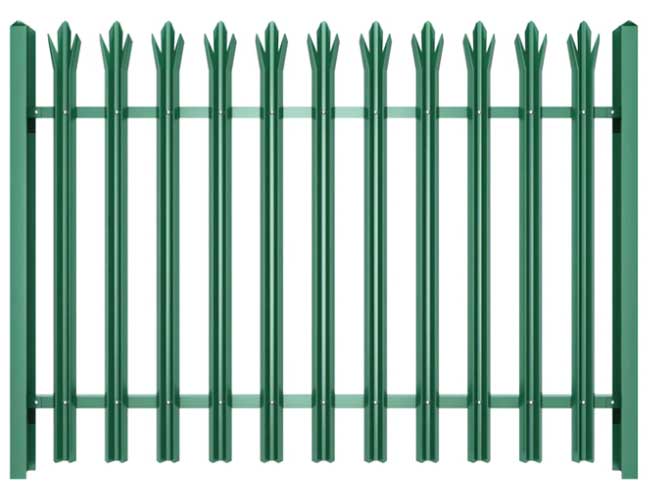

What Kind Of Fence Is Best For Your Yard 06. 04, 2021

What Kind Of Fence Is Best For Your Yard 06. 04, 2021 choose PVC fences during the purchase process 04. 22, 2020

choose PVC fences during the purchase process 04. 22, 2020 PVC fences are mostly used for municipal PVC fences 04. 22, 2020

PVC fences are mostly used for municipal PVC fences 04. 22, 2020 Detailed use of wire mesh fence 04. 22, 2020

Detailed use of wire mesh fence 04. 22, 2020 Advantages of Airport Fence 04. 22, 2020

Advantages of Airport Fence 04. 22, 2020 -

The role and advantages of airport fence nets 04. 22, 2020

The role and advantages of airport fence nets 04. 22, 2020 Features of Gabion Basket 04. 22, 2020

Features of Gabion Basket 04. 22, 2020 The steel wire mesh cage 04. 22, 2020

The steel wire mesh cage 04. 22, 2020

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: +86 180 3241 2189

- Ajouter.:No.69-70 La partie industrielle du filtre d'Anping, Hebei, Chine