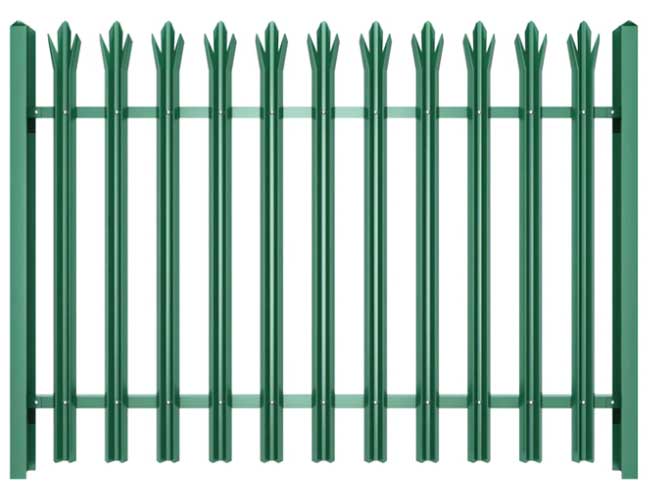

How to prevent rust on prison fence

Dip is an embodiment of anti-rust treatment. In real life, the iron wire may be galvanized wire exposed at the outer length of time, especially the iron wire soaked in rain will soon show rust or even decay. Then the prison fence net It is also made of wire, and when prisons generally purchase such products, they expect it to be more durable.

Currently, there are two methods of dipping and spraying. We may literally see that they are basically the same. In fact, otherwise, there are many differences in the process used. The dipping products are based on steel. The entire raw material is immersed in the solute steel.

The processed fence net has many advantages such as anti-corrosion and anti-rust, acid and alkali resistance, moisture resistance, aging resistance, long environmental protection and long life. Compared with dip molding, the spray-type processing technology is mainly sprayed with thermoplastic powder coatings, and some polyethylene and polytetrachloroethylene are commonly used as exterior coatings.

-

What Kind Of Fence Is Best For Your Yard 06. 04, 2021

What Kind Of Fence Is Best For Your Yard 06. 04, 2021 choose PVC fences during the purchase process 04. 22, 2020

choose PVC fences during the purchase process 04. 22, 2020 PVC fences are mostly used for municipal PVC fences 04. 22, 2020

PVC fences are mostly used for municipal PVC fences 04. 22, 2020 Detailed use of wire mesh fence 04. 22, 2020

Detailed use of wire mesh fence 04. 22, 2020 Advantages of Airport Fence 04. 22, 2020

Advantages of Airport Fence 04. 22, 2020 -

The role and advantages of airport fence nets 04. 22, 2020

The role and advantages of airport fence nets 04. 22, 2020 Features of Gabion Basket 04. 22, 2020

Features of Gabion Basket 04. 22, 2020 The steel wire mesh cage 04. 22, 2020

The steel wire mesh cage 04. 22, 2020

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: +86 180 3241 2189

- Ajouter.:No.69-70 La partie industrielle du filtre d'Anping, Hebei, Chine