How to Prevent Galvanized Wire to Turn Black or Rust

If the galvanized wire becomes black from silver, it will affect the appearance and efficiency. In the process of galvanization, how to avoid black and protect galvanized wire this problem has been the research topic of Qunkun Metal Company. Note that the reasons are wet air, impurities in the raw materials of production, and the sanitation of the constructors will affect the galvanized zinc layer.

Here are simple methods that can prevent the galvanized surface of turning black or prolonging the silver color time during the production process:

1. For example, keep the work area dry, reduce and no use chemicals.

2. The operator should wear clean gloves to prevent sweat from attaching to the surface of the zinc layer to corrode the galvanized wire.

3. In addition,the factory can be required to passivate the zinc after galvanization. The passivated zinc has a better anti-discoloration effect and can effectively prolong the time of discoloration.

When these methods are used together, discoloration can be solved or improved .The above all the content brought by the wire manufacturer QUNKUN METAL COMPANY.If you want to know more information, please free contact us.

-

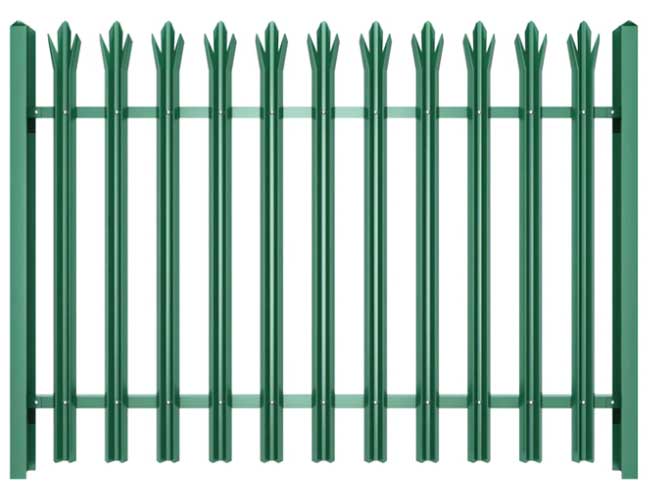

What Kind Of Fence Is Best For Your Yard 06. 04, 2021

What Kind Of Fence Is Best For Your Yard 06. 04, 2021 choose PVC fences during the purchase process 04. 22, 2020

choose PVC fences during the purchase process 04. 22, 2020 PVC fences are mostly used for municipal PVC fences 04. 22, 2020

PVC fences are mostly used for municipal PVC fences 04. 22, 2020 Detailed use of wire mesh fence 04. 22, 2020

Detailed use of wire mesh fence 04. 22, 2020 Advantages of Airport Fence 04. 22, 2020

Advantages of Airport Fence 04. 22, 2020 -

The role and advantages of airport fence nets 04. 22, 2020

The role and advantages of airport fence nets 04. 22, 2020 Features of Gabion Basket 04. 22, 2020

Features of Gabion Basket 04. 22, 2020 The steel wire mesh cage 04. 22, 2020

The steel wire mesh cage 04. 22, 2020

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: +86 180 3241 2189

- Ajouter.:No.69-70 La partie industrielle du filtre d'Anping, Hebei, Chine