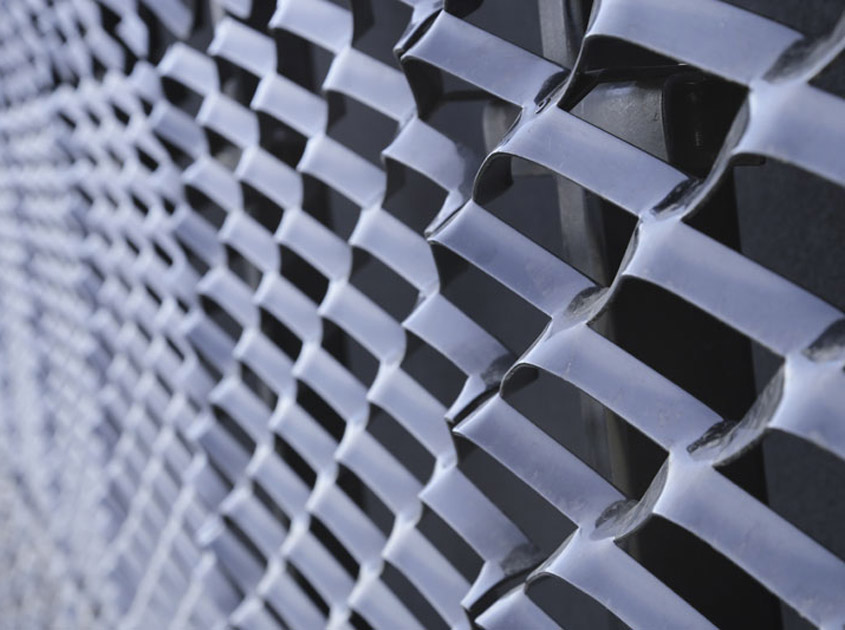

Anti-rust principle of expanded metal

The reason of wire mesh rust prevention:

First, change the internal organization of the metal

For example, to make various corrosion-resistant alloys, such as stainless steel in chromium and nickel in shallow steel.

Second, the maintenance layer method

Protect the maintenance layer on the metal surface to isolate the metal products from the surrounding corrosive medium, and then prevent corrosion.

For example: 1. Apply oil, petroleum jelly, paint or protective enamel, plastic and other non-metallic materials on the surface of the expanded metal mesh.

2. Electroplating, hot plating, thermal spraying and other methods are used to plate a layer of metal that is not easily corroded, such as zinc, tin, chromium, and nickel. These metals often form a dense oxide film due to oxidation, and then prevent water and air from corroding steel.

3. A fine and constant oxide film is formed on the steel surface by chemical method. For example, a fine black iron oxide film is formed on the surface of steel parts such as mechanical parts and guns.

Three, electrochemical maintenance method

Electrochemical maintenance method uses galvanic cell affairs for metal maintenance, trying to eliminate galvanic cell reverberation. Electrochemical maintenance methods are divided into anode maintenance and cathode maintenance. The more commonly used is the cathodic maintenance method.

IV. Dealing with corrosive media

Eliminates corrosive media, such as often cleaning metal equipment, placing monotonous agents in precision instruments, and participating in small amounts of corrosion inhibitors that can slow down the corrosion rate in corrosive media

-

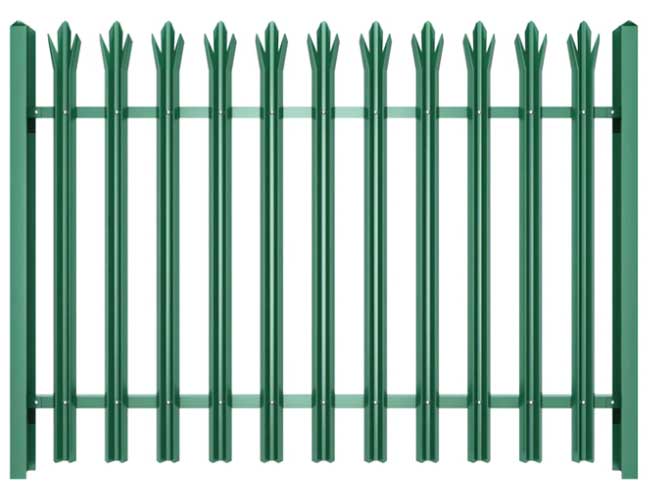

What Kind Of Fence Is Best For Your Yard 06. 04, 2021

What Kind Of Fence Is Best For Your Yard 06. 04, 2021 choose PVC fences during the purchase process 04. 22, 2020

choose PVC fences during the purchase process 04. 22, 2020 PVC fences are mostly used for municipal PVC fences 04. 22, 2020

PVC fences are mostly used for municipal PVC fences 04. 22, 2020 Detailed use of wire mesh fence 04. 22, 2020

Detailed use of wire mesh fence 04. 22, 2020 Advantages of Airport Fence 04. 22, 2020

Advantages of Airport Fence 04. 22, 2020 -

The role and advantages of airport fence nets 04. 22, 2020

The role and advantages of airport fence nets 04. 22, 2020 Features of Gabion Basket 04. 22, 2020

Features of Gabion Basket 04. 22, 2020 The steel wire mesh cage 04. 22, 2020

The steel wire mesh cage 04. 22, 2020

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: +86 180 3241 2189

- Ajouter.:No.69-70 La partie industrielle du filtre d'Anping, Hebei, Chine